Conformal Coating ECC3011 and ECC3051S: Superior corrosion protection in harsh environments

As experts in coating materials, we would like to introduce a new innovation in the world of Conformal Coating: ECC3011 and ECC3051S coatings from Momentive High-tech Materials. These coatings employ a unique formulation that offers inherent resistance against the elements that cause corrosion in electronic components.

In this article, we want to explore why corrosion protection in electronic components is so important, what Conformal Coatings - also known as Thixotropics - are, and why ECC3011 and ECC3051S coatings are a superior solution for corrosion protection in harsh environments.

Why is corrosion protection of electronic components important?

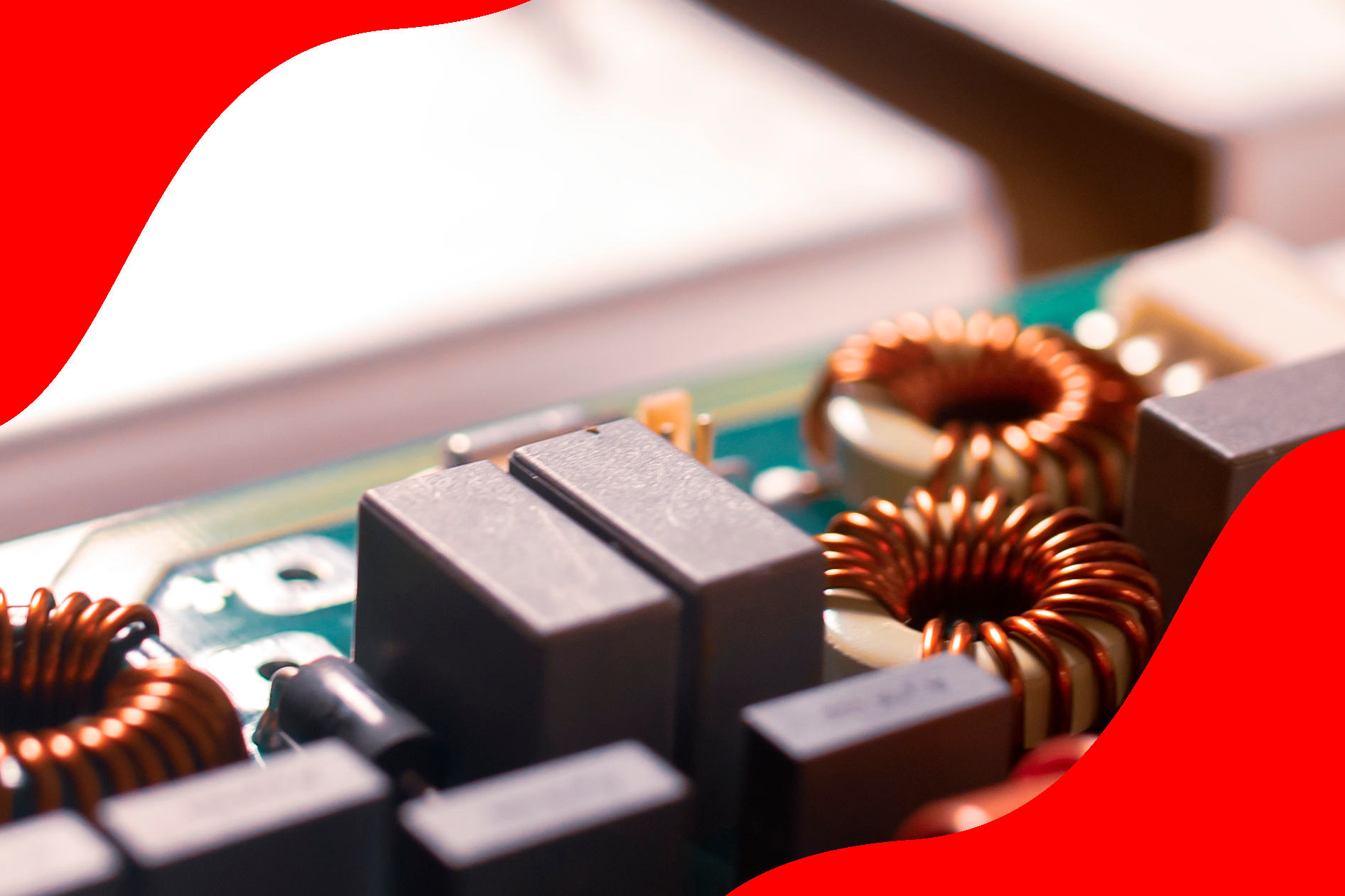

Electronic components can be exposed to harsh environments, such as humidity, salt spray and other environmental factors that can cause corrosion and wear on component materials. Corrosion can damage electronic components, reduce their service life and affect their performance.

Corrosion protection is essential to ensure the reliability and performance of electronic components in harsh environments. Conformal coatings are an effective solution to protect electronic components against corrosion and other environmental factors.

What are Conformal Coatings?

Conformal coatings are coating materials applied to electronic components to protect them against corrosion and other environmental factors. These coatings are commonly applied to PCBs (printed circuit boards), which are critical in most electronic devices.

Conformal coatings must have high corrosion resistance, strong adhesion and good compatibility with component materials. In addition, they must be easy to apply and cure quickly at room temperature.

What makes ECC3011 and ECC3051S coatings superior to other conformal coating materials?

Momentive High-tech Materials' ECC3011 and ECC3051S coatings are a superior solution for corrosion protection in harsh environments. These coatings employ a unique formulation that provides inherent resistance against the elements that cause corrosion in electronic components.

In tests conducted by Momentive in accordance with IEC standards, Momentive's silicone formulations outperformed other conformal coating materials for corrosion prevention, including acrylics, polyurethane, polyolefin and competitive silicone formulations.

ECC3011 and ECC3051S coatings have a low viscosity and solvent-free formulation, making them ideal for spray applications. In addition, they cure quickly at room temperature, which helps improve the efficiency of the production process. These coatings also contain fluorescent indicators that help verify a uniform coating under a black light.

Key benefits of ECC3011 and ECC3051S coatings

In addition to their superior corrosion resistance, ECC3011 and ECC3051S coatings offer strong adhesion, which helps protect electronic components from vibration and other environmental factors that can wear coating materials. They are also highly temperature resistant, making them an ideal solution for harsh environment applications.

In summary, the key benefits of ECC3011 and ECC3051S coatings are:

- Superior corrosion resistance

- Strong adhesion

- Temperature resistance

- Low viscosity

- Solvent-free formulation

- Fast cure at room temperature

- Fluorescent indicators to verify a uniform coating

In what applications are ECC3011 and ECC3051S coatings ideal?

ECC3011 and ECC3051S coatings are ideal for applications in harsh environments where electronic components are exposed to moisture, salt spray and other environmental factors that can cause corrosion and wear on component materials. These applications include:

- Marine industry

- Aviation industry

- Automotive industry

- Outdoor electronic devices

- High humidity electronic devices

Conclusion

Momentive High-tech Materials' ECC3011 and ECC3051S coatings are a superior solution for corrosion protection in harsh environments. These coatings employ a unique formulation that provides inherent resistance against the elements that cause corrosion in electronic components.

In addition to their superior corrosion resistance, ECC3011 and ECC3051S coatings offer strong adhesion, temperature resistance, low viscosity, solvent-free formulation, fast cure at room temperature and fluorescent indicators to verify a uniform coating.

If you are looking for an effective solution to protect your electronic components against corrosion and other environmental factors in harsh environments, Momentive High-tech Materials' ECC3011 and ECC3051S coatings are an excellent choice. With these Conformal Coatings, you can be confident that your electronic components will be effectively protected to enhance their service life and performance. Ultimately, choosing ECC3011 and ECC3051S coatings for the protection of your electronic components can help ensure the reliability and performance of your electronic devices in harsh environments.

If you would like to learn more about ECC3011 and ECC3051S coatings, or if you would like to discuss how our coating materials can help protect your electronic components, please feel free to contact Adhesive Bonding. We are here to help you find the right protection solution for your needs.

All comments

1

1

1