LED Encapsulation Resins

.jpg)

ENCAPSULATED RESINS FOR LEDS

The first LEDs were used in electronic equipment as indicator lamps to replace incandescent bulbs. They were soon associated for numerical displays in the form of seven-segment alphanumeric displays, at the same time as they were incorporated in digital clocks.

Recent developments have already made it possible to use LEDs for ambient lighting in a variety of applications. LEDs have enabled the development of new display screens and sensors, and their high switching speeds also allow them to be used for advanced communications technologies.

In this post we are going to talk about LED encapsulation resins, for use in outdoor environments where humidity, water and other agents do not allow the incorporation of luminous solutions.

LED technology has revolutionized the world of lighting, both indoors and outdoors, allowing greater energy savings, greater durability in the life of the light and the possibility of attaching it to any surface.

Technologies exist to make LED lights effective and usable in any environment, protecting the electrical and electronic components from any type of external agent, guaranteeing a long life and increasing reliability, we are talking about LED encapsulation.

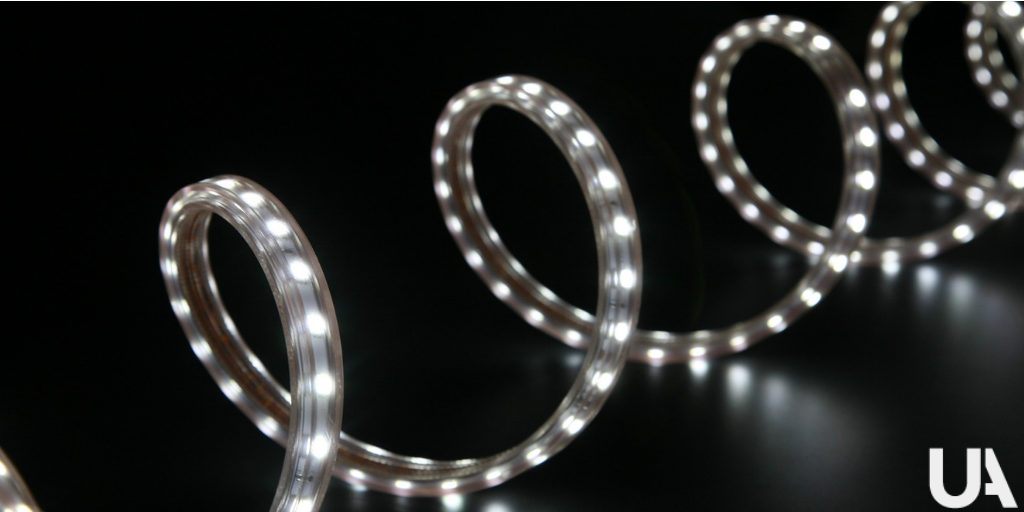

The use of this encapsulation process with specific resins for this use, has allowed to cover and protect the LEDs in a way that was previously unimaginable to achieve, creating flexible LED strips and we can create LED profiles that can be adapted to any type of paving.

It reaches an IP68 protection level, which allows its use under any type of liquid or its placement and operation in any type of environment, either indoors or outdoors. Getting to make designs with flexible LED elements, encouraging the imagination of designers, architects and engineers.

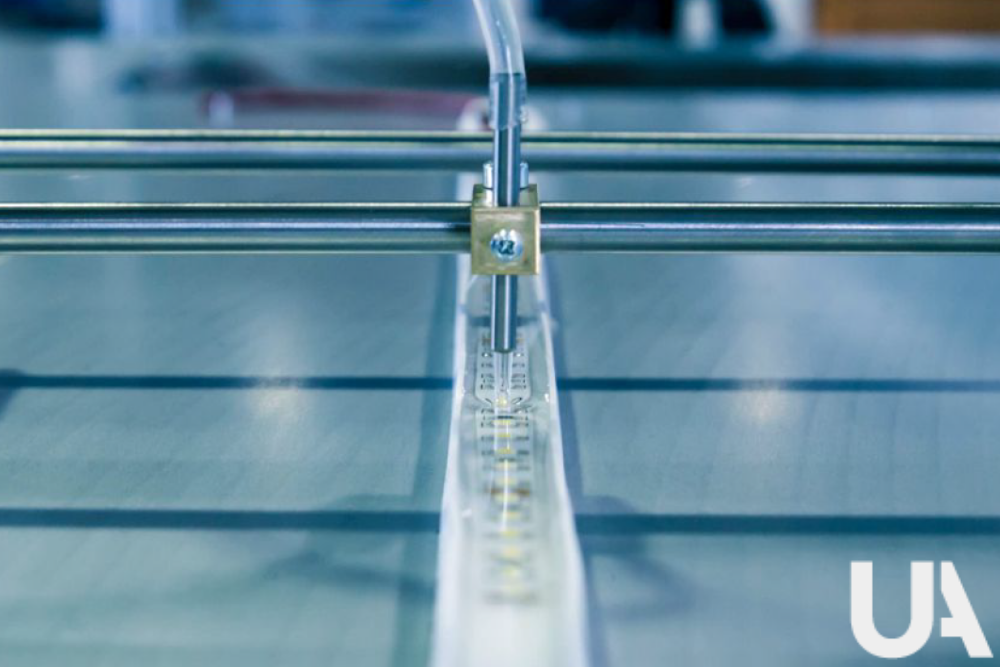

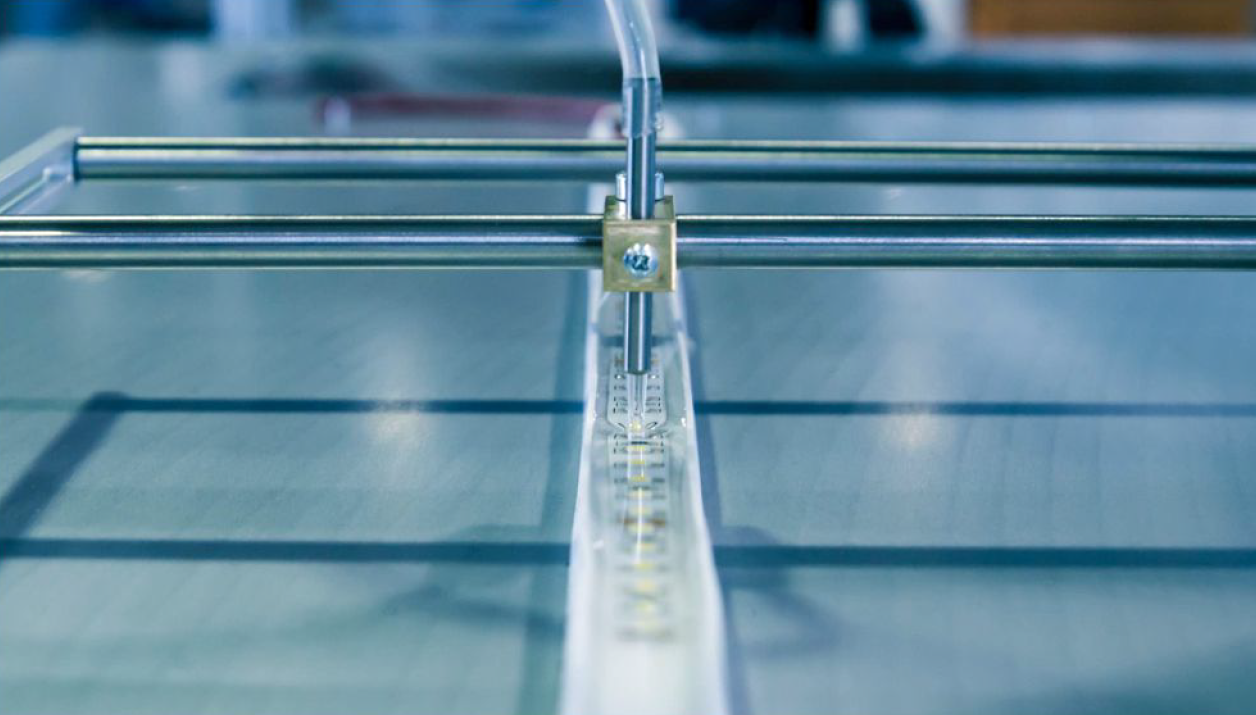

Encapsulation Process

Aliphatic polyurethane resins of different degrees of hardness are used, from 18 ShoreD to 80 ShoreD. At the time of encapsulation, it is necessary to use a machine to dispense the resin with vacuum technology to avoid bubbles. There is a wide range of this type of machines on the market to perform any type of potting.

The use of the right resin guarantees the success of our encapsulation process, getting the maximum performance out of the product. The use of the right resin is the secret to obtain the best final result.

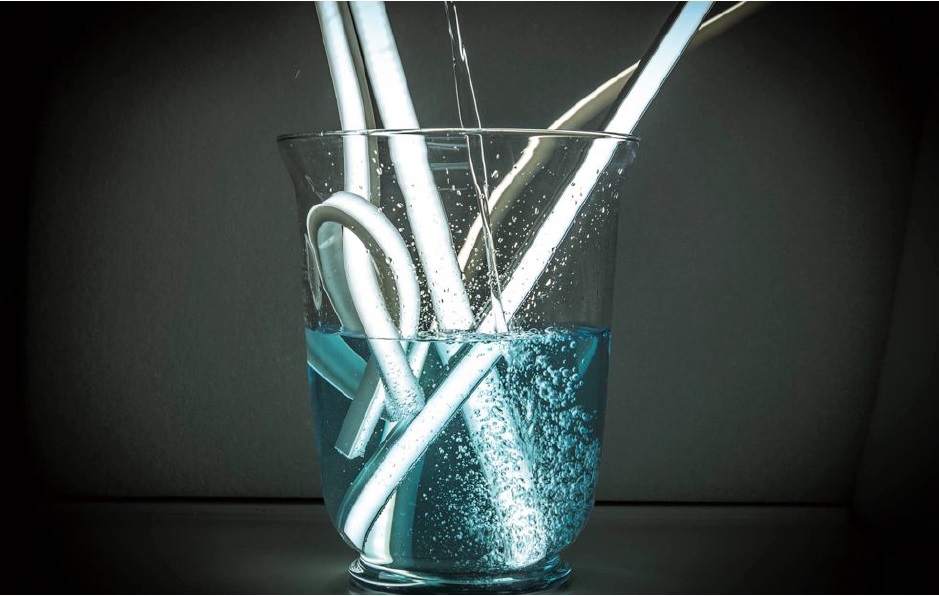

"Waterproof" IP68 protection

What does IP68 Protection mean? It is the highest level of protection in adverse working conditions, it allows the object to be immersed for an indefinite period of time, and not to suffer any type of filtration of water or dust, 100% protected.

By applying this protection to the LED encapsulation, we allow these LEDs to be used in any type of environment, outdoor, indoor or even under liquid, being able to make finishes with LED profiles or LED flexible strips, an optimal result both in interiors of swimming pools, fountains, facades and any type of lighting that is needed outdoors.

Resins, epoxies, Silicone

Epoxy

Epoxy products have a high resistance to thermal shock, their application has a high tolerance to high temperatures, in addition to a high resistance. These products, free of toxic materials, also have a versatility that allows them to be supplied in a wide range of applications for potting and bonding in both electrical and electronic processes.

Silicone

Silicone is an inorganic polymer derived from polysiloxane and, in addition to being an Eco-friendy product, it offers the possibility of working with it in a temperature range from -75°C to +200°C.

Urethane Polymer

These resins are an industrial product and their hardness and elasticity properties can be altered, but once they have settled into their final form, they do not return to their original shape. Urethane polymer is a great alternative to silicone, as long as the application does not require high temperature resistance. In fact, we can see that the potting of electronic components with urethanes works best at low temperatures. Urethanes do a great job of protecting stress-sensitive electronic devices. In addition, their properties prevent water from seeping in, better protecting electronic equipment.

In short, a good LED encapsulation is the result of the combination of the machine with the right resin, to create the right protection for the LED solution that we have to perform.

At Uniones Adhesivas, we advise you in your project, helping you in the choice of the right resin and if you need the encapsulation equipment, we guide you to find the perfect solution. Do not hesitate to contact us

Uniones Adhesivas, experts in adhesive solutions.

All comments

1