Why use UV-curable adhesives?

Are you familiar with ultraviolet light curing adhesives? These adhesives cure quickly when exposed to a specific ultraviolet wavelength and intensity depending on the material exposed. The speed translates into seconds of solidification, so waiting times are reduced to nothing. To help you make a safe choice, we at Uniones Adhesivas have set out to show you the main characteristics of ultraviolet curing adhesives..

Preliminary considerations

Before getting into the subject, we must take into account a series of considerations about our type of UV adhesives:

- Choosing the right ultraviolet equipment, allowing the right wavelength to be applied.

- Be aware of the material to be bonded, as each material has different curing times.

- Reduce its exposure to the sun, the sensitivity of these products to sunlight and artificial light is reason enough to keep it in dark areas.

How the curing process works

To activate the curing process, the energy given off by the ultraviolet light is absorbed by the photoinitiator molecules of the adhesive which are activated by the energy emitted from the ultraviolet light. These molecules form radicals, whose function is to initiate and accelerate the polymerization process resulting in the solidification of the adhesive in a few seconds.

Applications

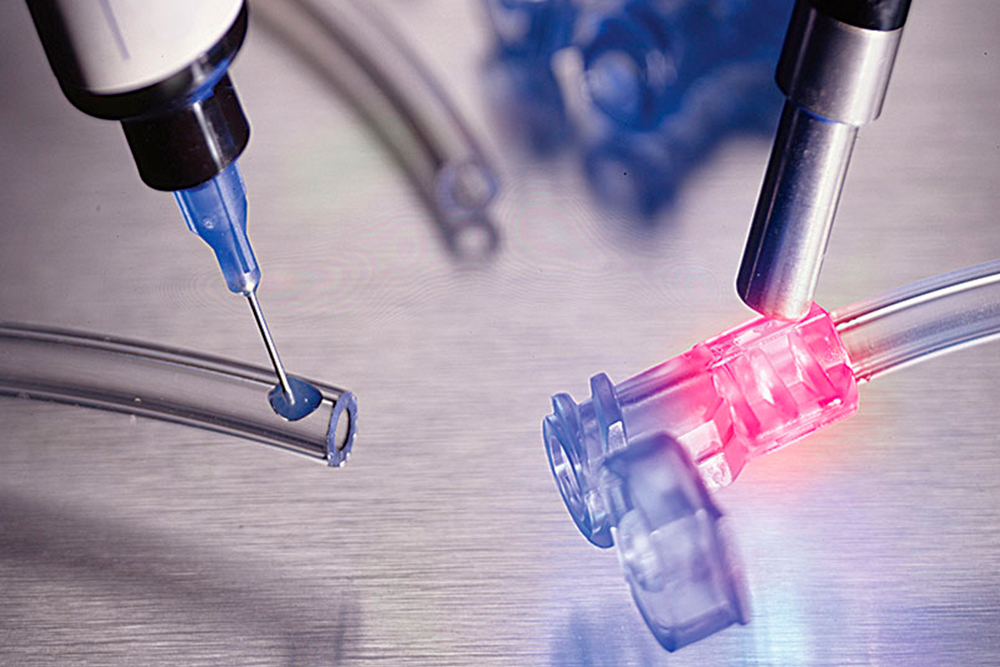

Since the curing process time with ultraviolet adhesives is short, many companies mass produce. Industries of various types employ these UV curing systems in a rather specific field of adhesives. The following list indicates some representative industries today:

- Medical (Medical instruments)

- Dental (Fillings)

- Decorative (glass furniture, vases and jewelry among others)

- Automotive (Sensors)

- Electronic (Electronic boards)

- Optical (Glasses to spectacle frames)

Benefits of UV-curable adhesives

Having UV-curable adhesives among our materials is, without a doubt, an obvious advantage for Adhesive Bonding. Primarily, UV adhesives cure only when exposed to ultraviolet light. Therefore, the a priori organization of the elements ensures the bonding of the different elements once the light is directed.

Cost reduction. The use of this type of adhesives in production is fast and the curing time is a matter of seconds, amortizing the same UV equipment.

The adhesives do not contain solvents. This allows for increased safety as they are non-flammable and improves environmental aspects.

Free choice of curing speed. The production speed will depend on the number of UV light units available. If a higher speed is required, simply add more units to the process.

They are completely solid materials. Unlike other liquid adhesives, UV curing adhesives do not cause any waste.

They are also single-component products. That means there is no need to be mixed with other elements.

UV-curable adhesives offer high-strength, high-quality bonds in all joints.

As you can see, UV curing adhesives can bring many benefits to your company. Tangible benefits in the long term. From Uniones Adhesivas we encourage you to use them. If you need more information, do not hesitate to contact us.Our experts at Uniones Adhesivas will offer you personalized advice.

All comments

Buenas tardes, mi nombre es Adriana Dos Santos, estoy estudiando ingenieria quimica, justamente en mi materia química industrial el profesor nos mandó a estudiar sobre el pegamento UV, la sintesis quìmica, equipos utilizados, componentes, etc. Con ustedes he logrado conseguir mas informaciòn, sin embargo, hablan de que se hace con un componente, cual seria este? si tienen un poco mas de informacion le agradeceria, es un trabajo que tengo que entregar en la universidad. gracias