UV and Light Curing

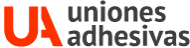

Generally the whole system functions in the following way: a liquid adhesive called monomer is filled with photo-initiators. When these initiators are activated by light they turn into so-called radicals and the polymerization process starts. Most UV adhesives are acrylic or epoxy based.

There are three main systems:

The product is applied to one of the mating parts. The two parts are assembled and then illuminated by UV light. Advantages of this radical system are as follows: Self determined open time for fixing parts, a very fast setting time after illumination and a high final shear strength. A limitation of this system is that at least one mating part has to be transparent and not block UV rays.

The second system is called cationic bonding. Firstly, the adhesive is applied and activated sufficiently by UV light. Then the parts are positioned and left to cure. Final strength is achieved without the need for further use of UV light and at room temperature. An advantage of this system is that the parts do not have to be transparent, nor do they have to allow UV rays to pass through them. A disadvantage is that the open time after illumination becomes short and total polymerization time is longer than previously described.

Thirdly and also popular are UV adhesives that are combined with secondary adhesion systems. Firstly there is an UV/anaerobic system where visible parts are polymerized by UV light, and the parts not exposed to UV light cure due to the absence of air and metal contact. Secondly, there is an option to cure the adhesive at a later stage by applying heat. This variation is very time and energy consuming and only applicable to certain substrates.

UV curing systems cover a very special field within the adhesive world. For example, glass bonding is impossible to achieve with Cyanoacrylates due to ageing problems and epoxies are just too slow. For these reasons, UV products are absolutely pre-destined for glass to glass or glass to metal applications and can be found in industries such as furniture manufacturing.

UV Curing Systems

- Radicals system

- Cationic

- UV Adhesives

Needing anything else? We compromise to reply you ASAP.